Cover Frames

A cover frame is the visible edge that neatly finishes your switches, outlets, and dimmers. It ensures a sleek look for flush-mounting and allows everything to blend seamlessly into your interior. Without such a cover frame, the technical parts are exposed, which is less visually appealing. The right cover frame not only enhances the appearance but also protects the technology beneath.

Different Types of Cover Frames

Cover frames are available in a variety of versions, each designed for specific applications and aesthetic preferences. The most common distinction is the number of 'modules' or 'elements' the frame can contain, ranging from single to multiple.

Single Cover Frames for One Function

This variant is suitable for a single switch, socket, or dimmer. It creates a sleek and minimalist finish when only one function per location is required. Single cover frames are often used in spaces where aesthetic simplicity is key, such as individual light points or outlets. The standard dimensions for a single cover frame are around 80 x 80 mm.

Multiple Cover Frames for Various Functions

Multiple cover frames can house two, three, four, or even five modules side by side. They are ideal for situations where several functions converge in one place, such as a combination of switches and a socket, or various dimmers. This contributes to a tidy appearance and reduces the number of visible edges on the wall. Multiple cover frames can be mounted either horizontally or vertically, depending on the required orientation.

The general dimensions of multiple cover frames vary based on the number of modules. A typical double cover frame measures approximately 80 x 151 mm, while a triple frame is about 80 x 222 mm. These standard sizes ensure compatibility with most flush-mounting boxes, whether mounted horizontally or vertically.

Technical Specifications That Define a Cover Frame

When selecting a cover frame, various technical specifications are important to ensure functionality, safety, and a proper installation. These features influence the usability and durability of the product.

Degree of Protection (IP Rating) Against Water and Dust

The IP rating (Ingress Protection) indicates the level of protection the cover frame offers against the ingress of solid objects (dust) and liquids (water). For switching equipment in dry indoor areas, IP20 or IP21 is usually sufficient. For damp areas like bathrooms or kitchens, cover frames with a higher IP rating—often IP44 in combination with a sealing set—are required to guarantee splash resistance. Always verify the required IP class for your specific installation location.

Material Quality and Influence on Durability

Cover frames are produced from several plastics, such as thermoplastic or duroplast. Thermoplastic cover frames are more flexible and generally more affordable, while duroplast is known for its hardness, scratch resistance, and heat resistance, resulting in a sturdier and more durable product. Both materials are often halogen-free, contributing to fire safety by emitting fewer toxic fumes in case of fire.

Mounting and the Depth of Cover Frames

The depth of a cover frame (usually between 9 and 12 mm) is an important measurement to consider, especially with shallow mounting boxes. The cover frame is placed on the base elements and closes off the assembly, making the total depth of combined components crucial for a flush wall finish. Fixing is typically done using clip fastenings on the modules themselves, ensuring an invisible and sleek installation.

Flexible Mounting: Horizontal and Vertical

Most cover frames are designed for both horizontal and vertical mounting. This offers flexibility during installation, depending on the orientation of the mounting box or the desired aesthetic. This feature is especially relevant for multiple cover frames, where the orientation can influence the functionality of the connected elements.

Materials and Colors That Define Appearance

Beyond functionality, materials and colors play a key role in the aesthetics of a cover frame. The material impacts durability, feel, and the final look in a space. Plastic is the most common choice, available in various finishes and colors, including:

- Plastic: The standard due to its durability, ease of cleaning, and wide range of available colors. Popular options include polar white (matte) and pure white (glossy), as well as cream, anthracite, and black variants.

- Glass: Glass cover frames offer a modern and luxurious look, often in black or white. They're scratch-resistant and reflect light, adding a sense of depth.

- Metal: Stainless steel, aluminum, or bronze variants provide an industrial or classic look and are very robust.

- Natural materials: For exclusive projects, there are cover frames made of wood, slate, or concrete, which give a unique character to the space.

The color and material should be matched to the interior and the desired ambience. A white cover frame provides a neutral and timeless look, while black or anthracite can offer a modern contrast. For a minimalist appearance, people often choose a frame that matches the color of the wall.

Practical Installation of a Cover Frame

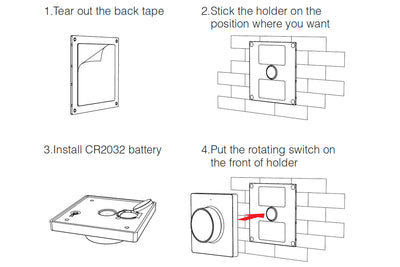

Mounting a cover frame is relatively simple but requires precision for a neat result. The cover frame is fitted after the base elements (switch, outlet, dimmer) have been correctly installed in the mounting box and electrically connected.

- Ensure safety: Always turn off the power in the fuse box before beginning installation or removal of switchgear. This is crucial to prevent electrical shock.

- Install the base element: Securely mount the switch or outlet in the mounting box with the appropriate screws or clamps. Ensure proper alignment with the wall.

- Attach the cover frame: The cover frame clicks or screws onto the base element or mounting frame. In most modern series, it simply clicks onto the module(s), so no screws are visible.

- Place the central plate/rocker: As the final step, click or screw in the central plate (for a socket) or rocker (for a switch) into the cover frame.

- Check the installation: Check that everything is firmly in place and there are no gaps. Then turn the power back on.

Frequently Asked Questions About Cover Frames

Are cover frames interchangeable?

Cover frames are not universally interchangeable between all manufacturers. Each brand—and often even specific series within a brand—has unique dimensions and fastening systems that ensure compatibility with their own base elements. It is therefore important to stay within the same product line for a seamless fit and functionality.

What is the difference between a cover frame and a central plate?

A cover frame is the outer, decorative frame that sits around the modules of switchgear. A central plate is the inner part that sits directly on the function (for example, the part where you plug into a socket, or the rocker of a switch). Both are needed for a complete and safe installation.

Can a cover frame be used horizontally and vertically?

Yes, most multiple cover frames can be mounted both horizontally and vertically. This is often explicitly mentioned in the manufacturer's product information or manual, offering flexibility in the design and placement of the installation.

Which factors influence the lifespan of a cover frame?

The lifespan of a cover frame is mainly influenced by the quality of the material used (duroplast is usually more durable than thermoplastic), the degree of exposure to UV light (which can cause discoloration), and physical impact. Correct installation also contributes to long-term stability and durability.

Choose the Right Cover Frame for a Professional Installation

A cover frame is more than just a trim; it is an essential element that determines the functionality, safety, and appearance of your switchgear. By considering technical specifications, choice of material, and proper installation, you achieve a sustainable and aesthetically responsible electrical installation.